At Sanyo Chemical, we believe that it is important to work together across the entire supply chain to improve CSR while also working with our suppliers on procurement. Following our signing of the United Nations Global Compact in March 2021, we reviewed our Purchasing Policy and revised it as our Sustainable Purchasing Policy in January 2022.

Sustainable Purchasing Policy

- In addition to complying with laws and regulations, we will conduct procurement activities with social common sense based on corporate ethics, and strive to build relationships of mutual cooperation and trust with our business partners.

- We will provide fair trade opportunities for both domestic and overseas companies, and conduct procurement activities from a global perspective.

- In procurement activities, we will consider various conditions such as the quality, price, and stable supply of materials and raw materials. In addition, we will work with our business partners to maintain and improve appropriate pricing and quality. At the same time, we will promote green procurement, including environmental conservation and chemical substance management.

- We will aim to create a sustainable society through our supply chain, taking into account the efforts of our business partners to meet the corporate responsibilities demanded by society, such as consideration for the global environment and the protection of human rights and the working environment.

Sustainable Procurement

As a tool for working with our business partners to achieve a sustainable society, we have summarized what we would like our business partners to work on in our Sustainable Procurement Guidelines. The Guidelines present concrete actions based on the ten principles of the United Nations Global Compact from seven perspectives: sound corporate management, fair corporate activities, the environment, human rights, labor, quality and safety, and coexistence with local communities.

In addition to posting our Purchasing Policy and these Guidelines on our website, we attach them to requests for CSR questionnaires to suppliers to ensure they are widely known. CSR questionnaires are conducted annually targeting specific themes and corresponding business partners. In addition, the Purchasing Policy and these Guideline are translated into English and made known to the general public in order to support global procurement activities.

≫ Sustainable Procurement Guidelines

≫ Respect for Human Rights: Addressing Human Rights Issues Related to “Labor in the Supply Chain”

Promotion System

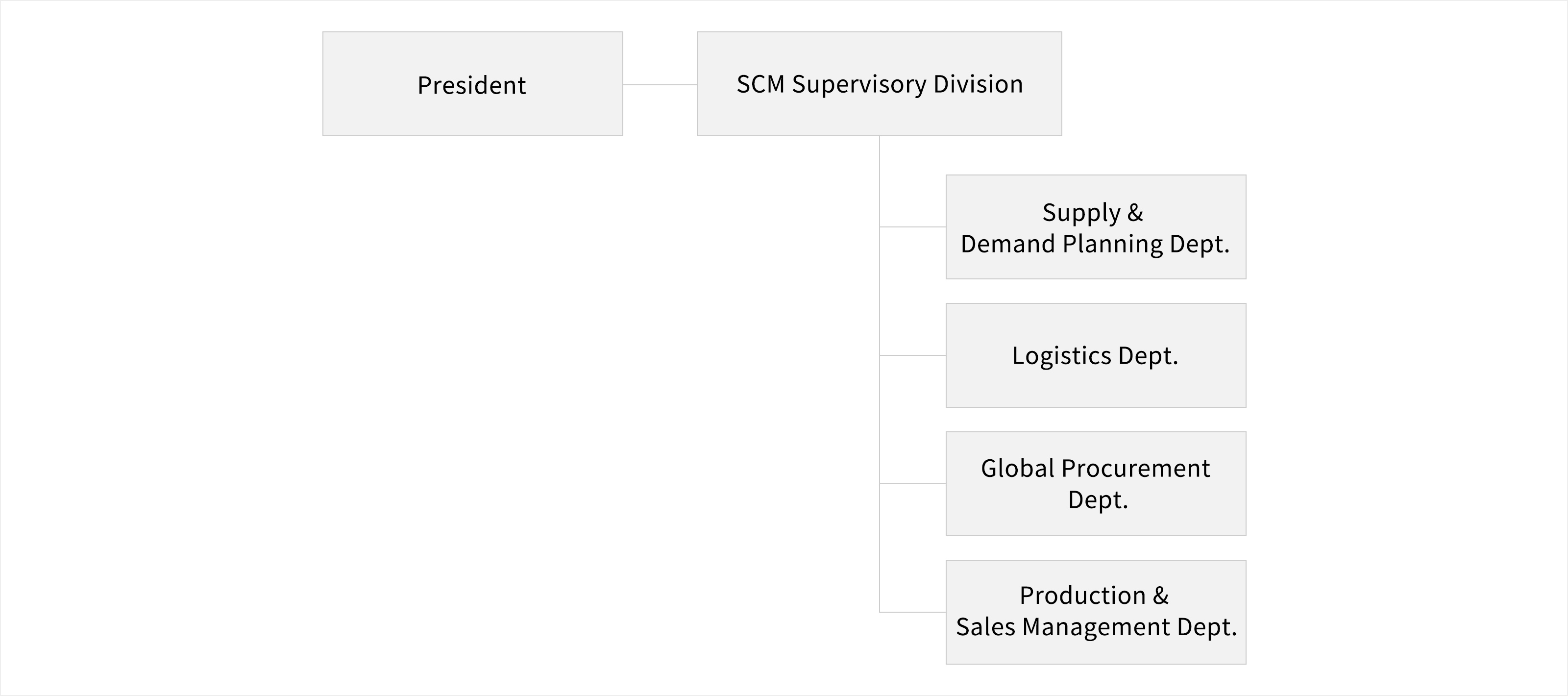

In October 2023, we established the SCM Supervisory Division to enhance the value of our entire supply chain by innovating Supply Chain Management (SCM) operations from the overall optimal perspective of the Sanyo Chemical Group and strengthening competitiveness through the creation of customer value. The SCM Supervisory Division consists of the Supply & Demand Planning Dept., the Logistics Dept., the Global Procurement Dept., and the Production & Sales Management Dept., and promotes the creation of a system that reliably delivers the necessary goods to the place where they are needed, when they are needed, in the quantities they need, with high quality and low cost.

System Diagram

When starting business transactions

We ask our business partners to submit the following documents when starting business transactions.

Based on their contents, we wish to work together to improve the level of sustainable procurement by understanding and evaluating the status of CSR activities, sustainable procurement, and green procurement promotion of our business partners and holding meetings to exchange views.

In FY2023, we held one meeting to exchange opinions with a business partner on the status of CSR activities.

Documents required for adoption

Raw material-related

(1) Delivery Specifications (Raw Materials) Excel

(2) Safety Data Sheet (SDS)

(3) Warranty certificate regarding chemicals contained in delivered products (Certificate of Non-use of RoHS 6 Restricted Substances) Excel

(4) Environmental and Chemical Substance Management Survey Sheet Excel

(5) CSR Questionnaire Excel

CSR Questionnaire

The CSR questionnaire uses the Self-Assessment Questionnaire (SAQ) of Global Compact Network Japan to quantify the extent to which the requirements of the United Nations Global Compact are met. Items that do not meet the requirements will now trigger a message prompting improvement.

In FY2023, we received questionnaire responses from 51 major raw material suppliers (approximately 10% of all suppliers). In FY2022, many of the target suppliers were large global companies and they obtained high evaluation points, but when the scope of target suppliers was expanded in FY2023, overall scores decreased. At present, we do not have any high-risk suppliers related to rare raw materials or raw materials imported from high-risk countries, but we will follow up with suppliers who have issues.

SAQ Response Results for Major Raw Material Suppliers

(Unit: %)

| FY2022 | FY2023 | |

|---|---|---|

| Human rights | 98 | 88 |

| Labor | 98 | 95 |

| Environment | 98 | 90 |

| Fair corporate activities | 100 | 89 |

| Quality and safety | 100 | 97 |

| Information security | 98 | 91 |

| Supply chains | 97 | 76 |

| Community | 98 | 88 |

- The results to all 114 questions (out of 5 points) are averaged for each evaluation item and displayed on a 100-point scale.

RSPO certification

We joined the Roundtable on Sustainable Palm Oil (RSPO) in 2013, and in January 2023, we obtained RSPO Certification with the Mass Balance (MB) model at our Head Office, the Tokyo Branch Office, and domestic factories (Nagoya Factory, Kashima Factory, and Kyoto Factory).

In FY2024, Sanyo Kasei (Thailand) Ltd. is also expected to obtain certification. As part of our supply chain management, our Group will ask our business partners to procure and use properly managed palm oil. We will also expand the use of certified sustainable palm oil to promote the procurement of sustainable raw materials and the establishment of a responsible supply chain.

ISCC PLUS certification

In May 2023, we obtained ISCC PLUS certification for biomass-derived polyethylene glycol (PEG) at our Tokyo Branch Office using the mass balance method. PEG is a polymer obtained by adding ethylene oxide to ethylene glycol or water, and is used in a wide range of applications, including industrial applications such as cosmetics, toiletries, and resins, as well as pharmaceuticals. We will continue to contribute to the realization of carbon neutrality through the utilization of biomass resources.

Conflict minerals

Our Sustainable Procurement Guidelines states that we will ensure transparency in our supply chain and will not be involved in the procurement of conflict minerals or crimes. We investigate the presence or absence of conflict minerals and the country of origin of the raw materials we procure, and we also require our business partners to do the same. We buy tin compounds, but we do not source them from conflict areas.

Implementation of a BCP for raw materials

In order to ensure business continuity in the event of a disaster (natural disaster, major fire, terrorist attack, etc.), we are promoting the implementation of a BCP for raw materials with the cooperation of our business partners. We are working on procuring raw materials from multiple sources, consolidating and eliminating similar raw materials, and securing multiple bases on the supplier side.